Steam Boiler

Steam Boiler

Clean & Lean Burn Wood Fired Boiler

Wood fired steam generator is low to high capacity steam boiler, no need for audits from Pollution control department.

It has advantages of rapid steam generation, with very less fuel consumption.

Compared to wood, gas & electric heating boiler, it can save 30%-80% running cost.

High efficiency & energy saving

Environmental

Stable & reliable

Convenient & efficient

High efficiency & energy saving

- Wood gasification combustion technology–Fuel burnout rate is over 98.5%.;

- Save cost up to 30-80% compared with traditional products.

- Heat conversion efficiency is over 70%

Environmental

- Wood as fuel– low-carbon,no sulfur and nitrogen emissions

- A closed loop mechanism ensures No smoke and minimal ash (85% less ash than conventional wood burning)

- No need of chimneys to treat exhaust flue gases.

Stable & reliable

Designed according to the standard process of boiler, each product is tested by water pressure, non-destructive testing, pressure holding, efficiency and stability, and strictly checked out with certificate.

Convenient & efficient

- Free of inspection;

- Compact structure, complete configuration with installation support

- Ignition, feeding, fire observation, ash removal, water level and other features in a user friendly design.

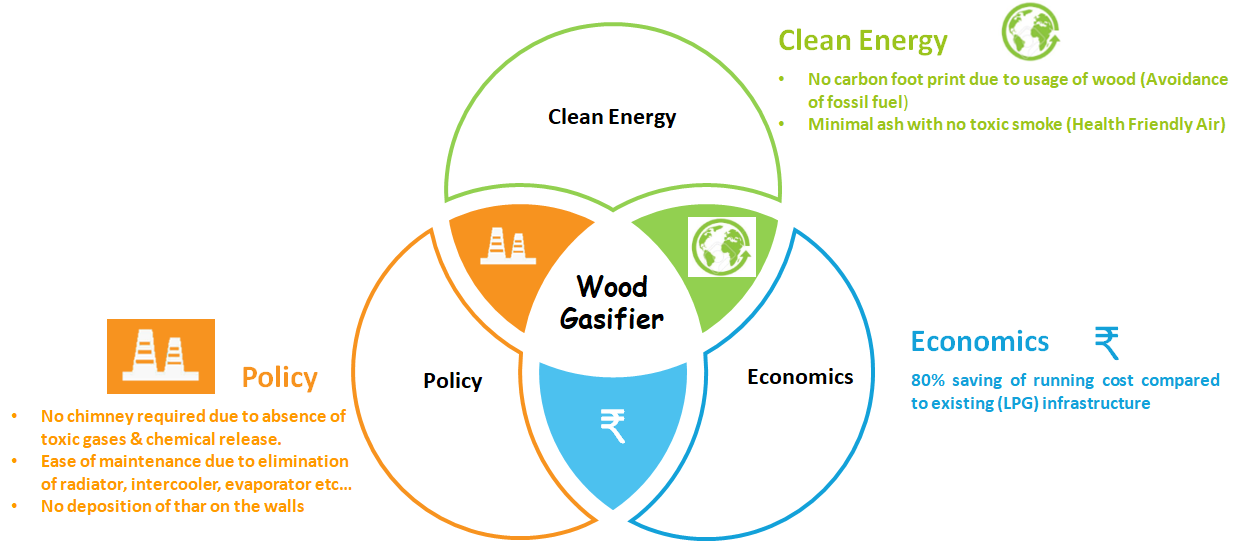

Clean And Lean Burn Technology

Process of Gasification

- Wood Gasifier system involves subjecting the wood pieces placed on the burning chamber for pyrolysis.

- This generates Producer gas which is burnt immediately at the upper periphery of the chamber through tiny apertures.

- Thus, dry wood which has a lower calorific value (heat generation potential) can be made effective and increase its calorific value by augmenting with gasification system.

- In conventional wood burning, ash content is 13~16% whereas by deploying Wood Gasifier system, generation of ash < 2% (complete & efficient combustion of wood). No residues of carbon particles & charcoal.

| Parameter | Coal | Wood | LPG | Gasified Wood |

|---|---|---|---|---|

| Raw Material | Coal | Rs 5 per kg | LPG | Wood |

| Calorific Value (max) | 4400 kCal per kg of coal | 2600 kCal per kg of wood | 11,000 kCal per kg of LPG | 4400 kCal per kg of wood |

| Material Cost | Rs. 12.5 per kg | Rs 5 per kg | Rs. 1600 per cylinder (17 kg) | Rs 5 per kg |

Need for our Product

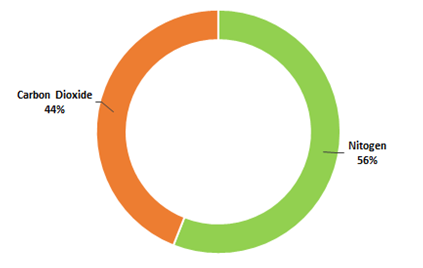

Producer Gas (Before Combustion)

Producer Gas (After Combustion)

For Boiler

Applications:

- Food Industry (Hotels, Catering etc…)

- Dairy Industry

- Noodles, Semiya, Pasta, Macaroni

- Water Distillation / Treatment

- Chemical Industry

- Rice / Paddy Processing

- Hospitals

- Hotels & Villas

- Steam Ironing